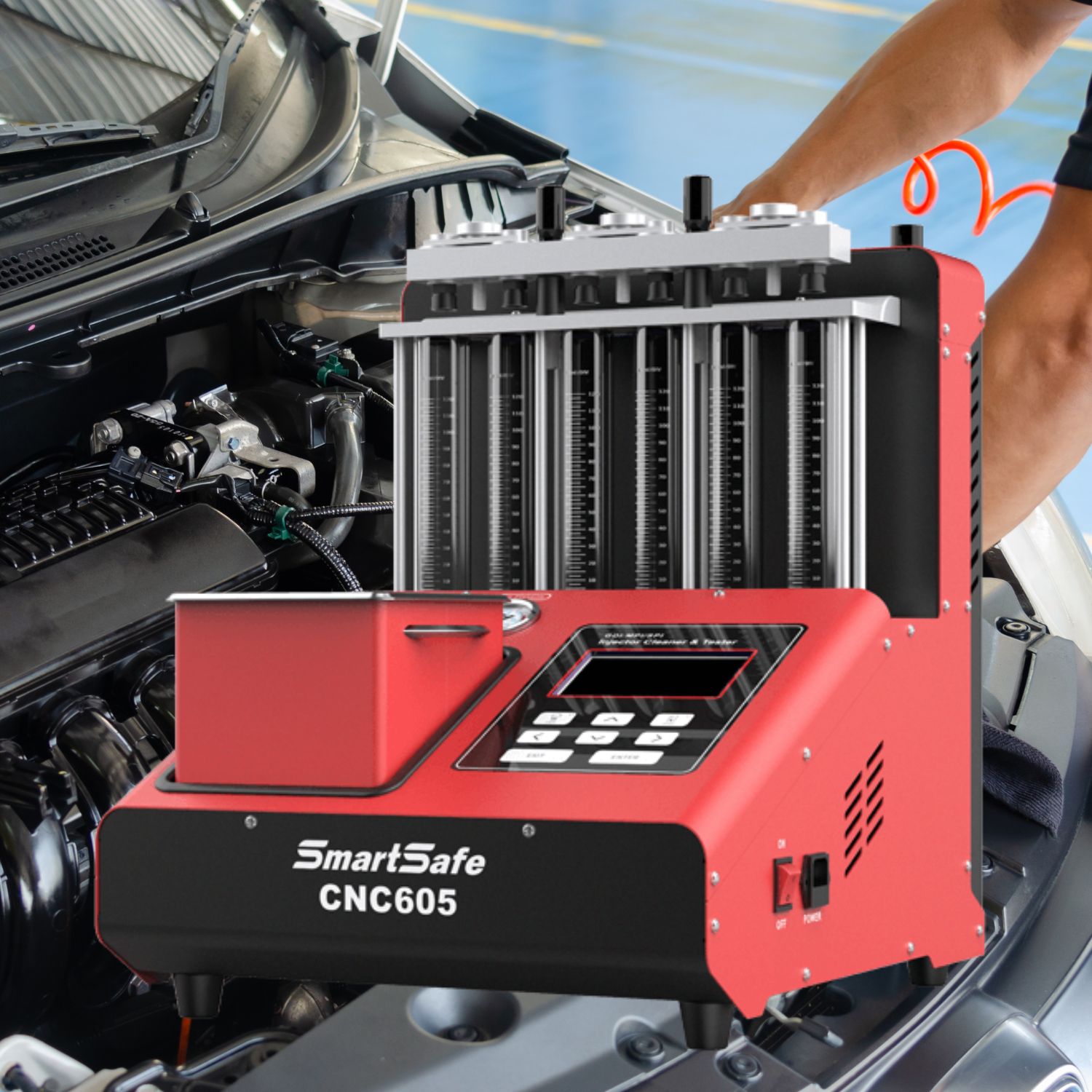

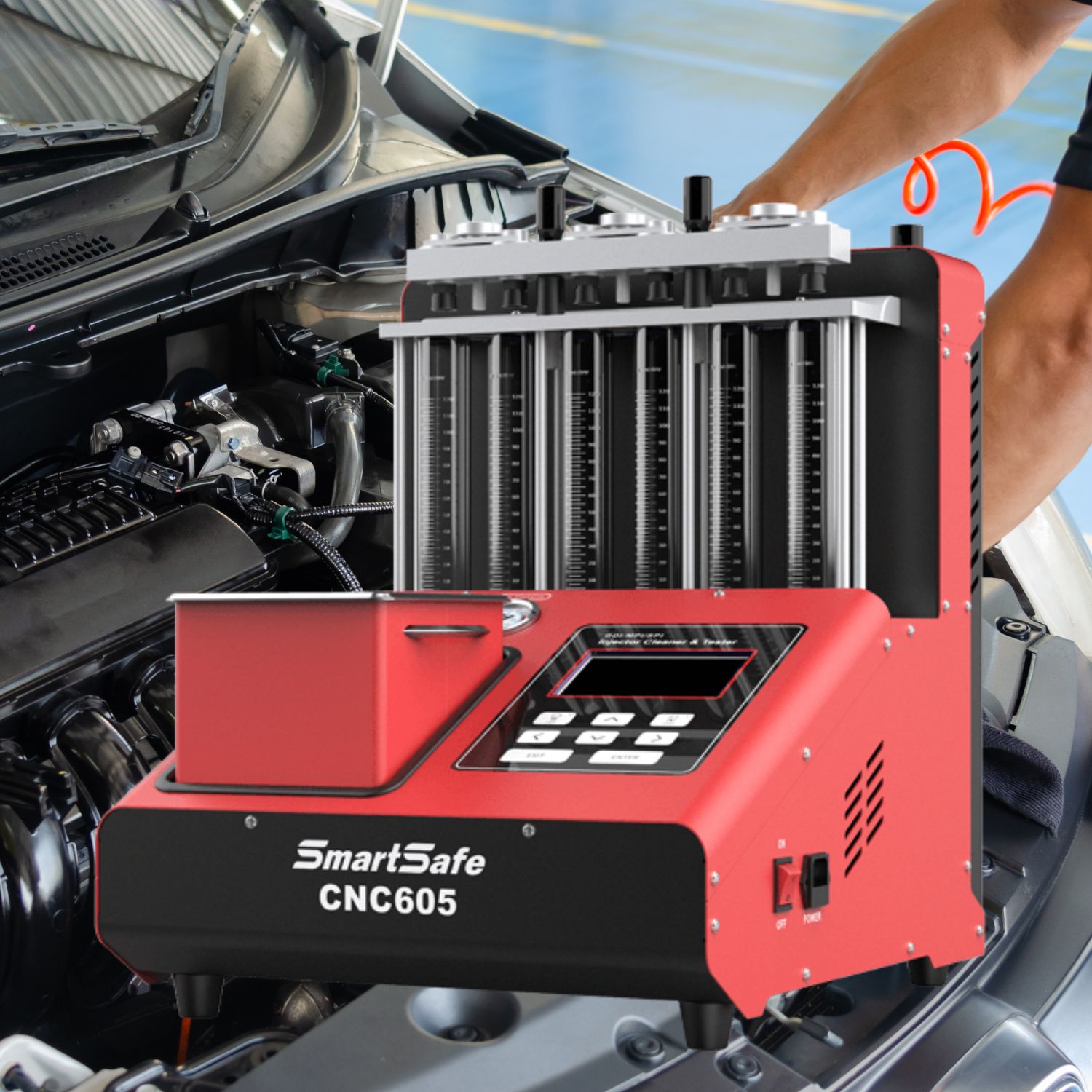

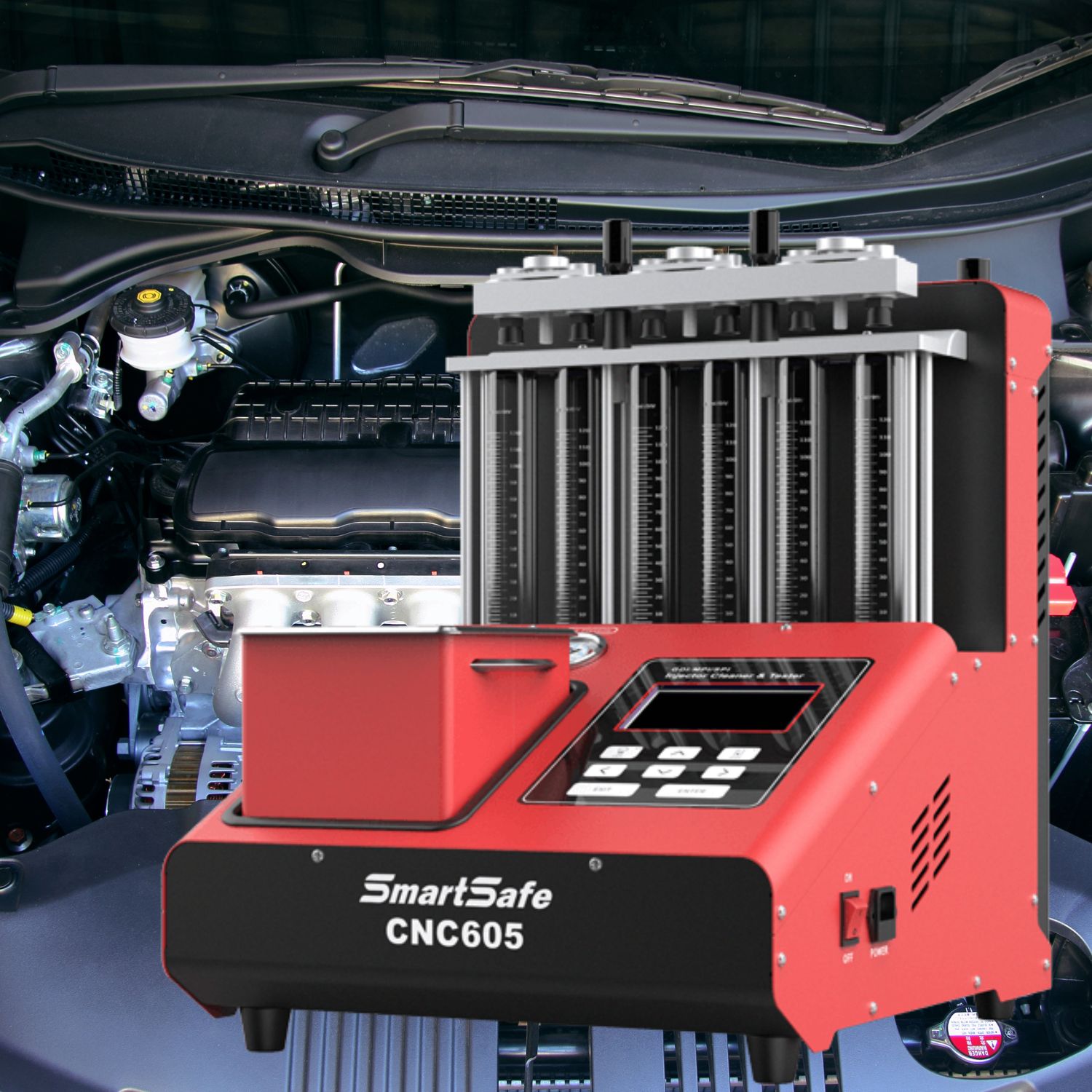

Fuel Injector Cleaning Machine CNC-605A

4.550,00 SAR Original price was: 4.550,00 SAR.3.700,00 SARCurrent price is: 3.700,00 SAR.

Car injector cleaning machine CNC-605A is the ideal solution for maintaining your vehicle’s fuel injection system and ensuring performance efficiency. With advanced technologies like ultrasonic cleaning and precise performance testing, the machine effectively removes carbon deposits and optimizes fuel flow. It features an innovative and user-friendly design with an LCD display and touch-sensitive buttons, making it an essential tool for both professional maintenance workshops and car owners looking to maintain their engine’s performance and reduce fuel consumption. Choose the CNC-605A for an integrated maintenance experience with fast results!

Launch Saudi Arabia offers a comprehensive warranty on the CNC-605A car injector cleaning machine, providing you with peace of mind and confidence in your investment. Additionally, the company offers complete technical support from a dedicated team ready to answer your inquiries and resolve any technical issues. The support doesn’t stop there, as the company is committed to continuous follow-up to ensure your complete satisfaction and the best user experience. With Launch Saudi Arabia, you’re not just purchasing a machine—you’re gaining a reliable partner who cares about the quality of your services and the success of your business.

214 in stock

Maya / Pre-sale Questions

Need Help? Contact Us via WhatsApp

Maya / Pre-sale Questions

Need Help? Contact Us via WhatsApp

Fuel Injector Cleaning Machine CNC-605A is an advanced device designed to effectively and precisely clean vehicle fuel injectors. It utilizes high-pressure technology to remove deposits and debris accumulated inside the injectors, helping to improve engine performance and reduce fuel consumption. This machine is the ideal solution for specialized centers and automotive repair workshops, as it helps maintain fuel system efficiency and enhances the overall lifespan of the engine.

Introduction to the CNC-605A Fuel Injector Cleaning Machine

The CNC-605A Fuel Injector Cleaning Machine is an innovative and advanced device specifically designed to effectively clean fuel injectors in vehicles. It is an ideal solution for enhancing engine performance and improving its efficiency. The machine utilizes advanced high-pressure cleaning technology to remove deposits and impurities that accumulate over time, ensuring the fuel system operates at optimal efficiency.

Many vehicle owners and repair workshops face challenges related to clogged injectors due to accumulated deposits and harmful substances, which result in reduced engine performance and increased fuel consumption. The CNC-605A provides a fast and effective solution to this issue, thoroughly cleaning the injectors to restore their ability to evenly distribute fuel, thus significantly improving overall engine performance.

Additionally, the CNC-605A is user-friendly and saves time and effort for maintenance technicians. It offers easy operation and efficient cleaning, making it the perfect choice for specialized centers and workshops aiming to enhance service quality and ensure peak vehicle engine performance.

Specifications of the CNC-605A Fuel Injector Cleaning Machine

- Advanced Cleaning Technology: Utilizes high-pressure technology for effective cleaning, removing deposits and impurities from the injectors with precision.

- Digital Display: Equipped with a digital display screen that clearly shows all data, facilitating process monitoring and control.

- Multiple Cleaning Modes: Offers various cleaning modes tailored to different vehicle types and service requirements, providing flexibility in operation.

- High Pump Pressure: Features a high-pressure pump for deep injector cleaning, restoring their efficiency and improving engine performance.

- Ease of Use: The machine is designed for simple and efficient operation, allowing technicians to perform cleaning procedures effectively without complications.

- Precision Measurement: Provides high accuracy in measuring fuel quantity used during the cleaning process, ensuring thorough injector cleaning.

- Compatibility with Most Vehicles: Works with a wide range of vehicle types, making it suitable for diverse maintenance workshops.

- Rust and Corrosion Resistance: Built with materials resistant to rust and corrosion, ensuring long-lasting durability even in harsh working conditions.

- Performance Indicators: Includes performance indicators to ensure precise operation during the cleaning process, delivering excellent results in minimal time.

- Comprehensive Technical Support: Backed by full technical support and periodic maintenance from Launch Saudi Arabia, ensuring consistent high efficiency.

Technical Specifications of the Device:

- Temperature: -10~+40℃

- Relative Humidity: Less than 85%

- External Magnetic Field Intensity: Less than 400A/m

- No exposed flames within 2 meters.

Benefits of Using the CNC-605A Fuel Injector Cleaning Machine for Injector Cleaning

- Improved Engine Performance: The CNC-605A fuel injector cleaning machine effectively removes deposits and impurities from fuel injectors, restoring their ability to distribute fuel evenly and enhancing overall engine performance.

- Increased Fuel Efficiency: By cleaning the injectors, the CNC-605A improves fuel distribution in the engine, reducing fuel consumption and boosting engine efficiency.

- Reduced Harmful Emissions: The machine helps eliminate deposits and materials that may cause incomplete fuel combustion, thereby reducing engine emissions and contributing to a cleaner environment.

- Extended Engine Lifespan: Keeping injectors clean reduces stress on other engine components, prolonging engine life and minimizing the need for costly maintenance.

- Enhanced Engine Responsiveness: Cleaning injectors with the CNC-605A restores the engine to optimal condition, improving throttle response and reducing lag during acceleration.

- Lower Maintenance Costs: Regular use of the CNC-605A for injector cleaning can prevent major issues requiring expensive repairs or injector replacement, saving on maintenance costs.

- Resolving Poor Performance Issues: If experiencing problems such as vibrations or loss of power while driving, the CNC-605A can address these issues by cleaning clogged injectors.

- Time-Efficient and Easy to Use: The CNC-605A simplifies the cleaning process, reducing the time needed for maintenance and making it a more efficient option for workshops.

- Compatibility with a Wide Range of Vehicles: This machine is suitable for various vehicle types, making it a versatile solution for workshops and specialized service centers.

- Effective and Reliable Results: The CNC-605A ensures deep and thorough injector cleaning, restoring optimal engine performance and enhancing the quality of service provided to customers.

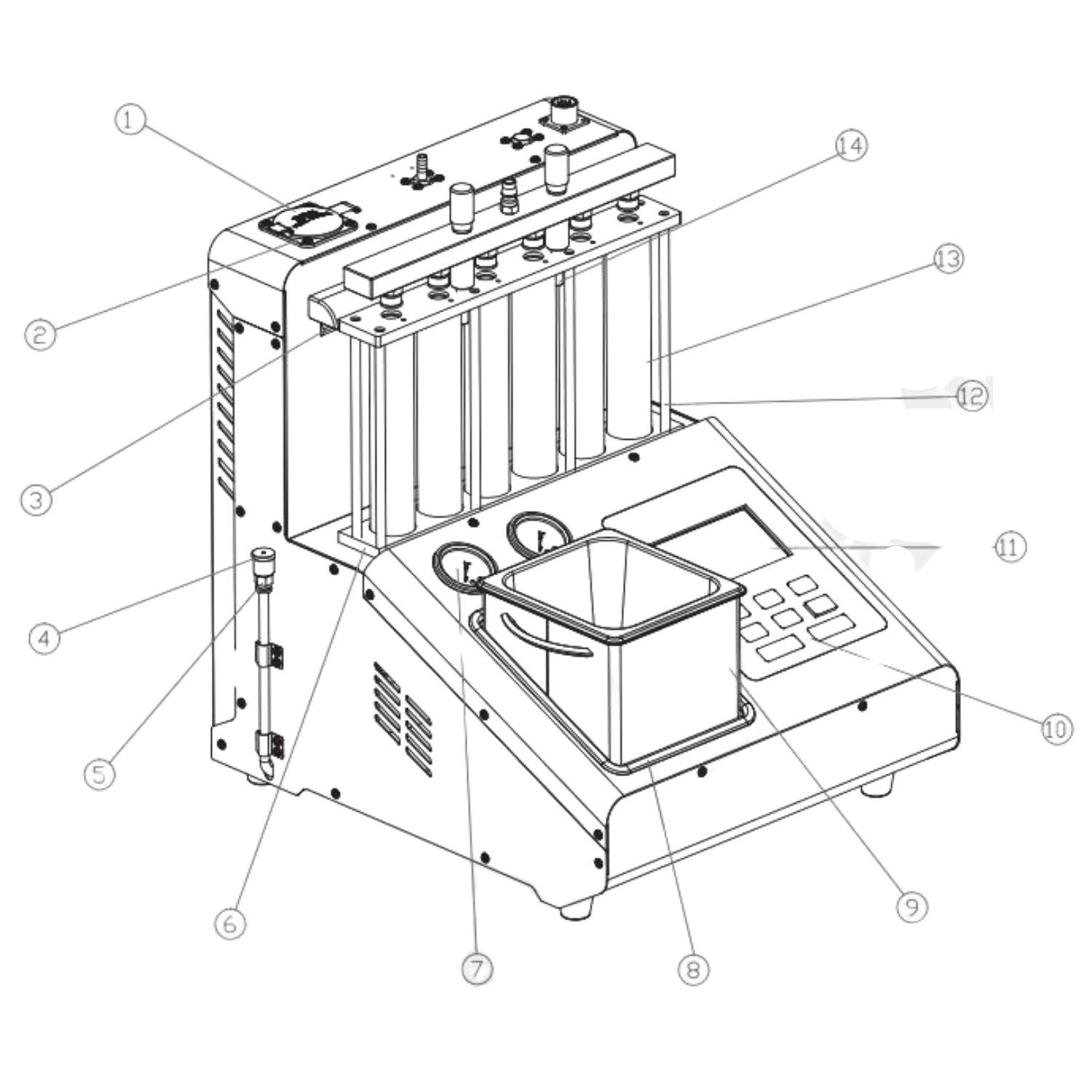

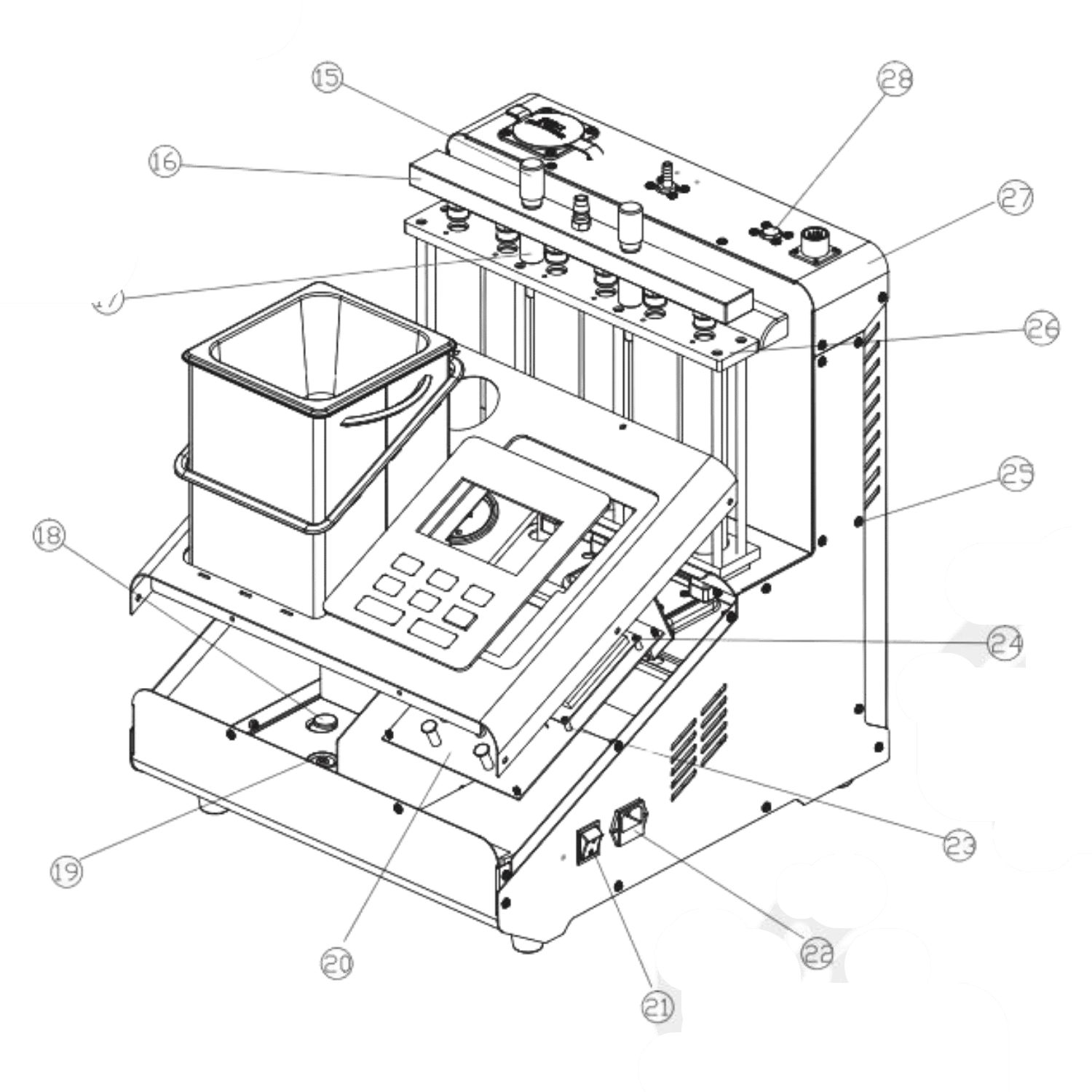

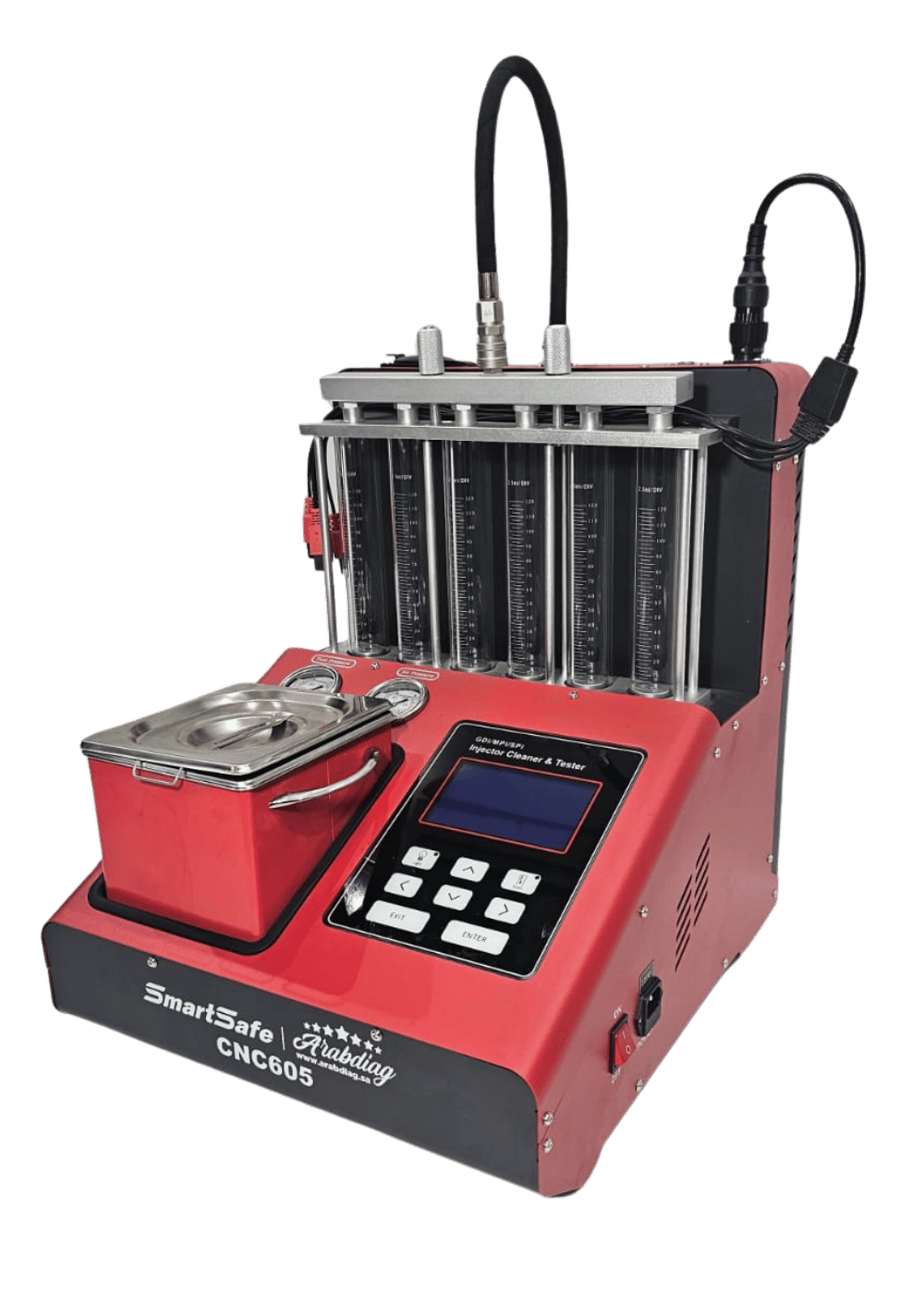

Explanation of the Components of the Fuel Injector Cleaning Machine CNC-605A

- Filling Port Cap: The cover that seals the filling port, preventing contaminants from entering and ensuring the liquid remains secure.

- Filling Port: The opening through which cleaning fluid is added to the machine.

- LED Light Strip: A strip of LED lights used to indicate the status of the machine or to provide visual cues during operation.

- Liquid Level Tube Cap: A cover for the tube that monitors and regulates the fluid level, ensuring proper liquid quantity for the cleaning process.

- Liquid Level Tube Connector: The connector that attaches the liquid level tube to the machine, allowing the liquid to be monitored and maintained.

- Lower Pressing Plate: A component that helps maintain pressure on the injectors during cleaning to ensure effective fluid flow.

- Pressure Gauge: A device that measures the pressure inside the system, indicating whether the cleaning process is being performed under the correct pressure levels.

- Silicone Protector for Ultrasonic Cleaner: A protective silicone cover used for the ultrasonic cleaner to prevent damage to components.

- Ultrasonic Cleaner: A device that uses ultrasonic waves to clean the fuel injectors by producing high-frequency sound vibrations.

- Glass Panel: A transparent surface that covers components and allows the user to view the machine’s interior or cleaning process.

- Monochrome Display Screen: A display screen that shows relevant data in a single color, providing visual feedback for the user.

- Fixing Rod: A rod used to secure and stabilize components or tools during the cleaning process.

- Glass Tube: A tube made of glass that holds the injectors during the cleaning procedure, allowing visibility of the process.

- Adjustment Screw: A screw used to fine-tune or adjust settings in the machine, ensuring optimal performance.

- Pressing Screw: A screw used to apply pressure or secure components to ensure the proper functioning of the machine during the cleaning process.

- Fuel Distributor: A component that ensures the even distribution of cleaning fluid to the injectors, ensuring efficient cleaning.

- Adjustment Nut: A nut used for making precise adjustments to certain parts of the machine, such as controlling pressure or fluid flow.

- Door Mat: A mat designed to be placed on the door area, protecting the equipment or surface from damage during operation.

- Power Supply Base: The base unit that connects to the power source, providing electrical supply to the cleaning machine.

- Control Panel: The interface with buttons and switches used by the operator to control and configure the machine’s settings.

- Power Switch: The switch used to turn the cleaning machine on and off.

- Power Socket & Fuse: The socket used for connecting the machine to an electrical outlet and the fuse to protect the machine from power surges.

- Copper Post: A copper post used as part of the electrical circuit or connector for the machine’s internal wiring.

- Screw: General screws used throughout the machine to secure components together.

- Screw: Additional screws used for various purposes, like tightening parts or securing the machine’s structure.

- Upper Pressing Plate: A plate that applies pressure to components during cleaning, working in conjunction with the lower pressing plate for effective cleaning.

- Cabinet: The external casing or housing that encloses the machine’s components, offering protection and a neat arrangement of parts.

- Copper Plug: A plug made from copper, used to seal or connect components in the machine, offering conductivity and durability.

How to Use the CNC-605A Car Fuel Injector Cleaning Machine

The CNC-605A car fuel injector cleaning machine is an advanced tool that helps improve engine performance by effectively cleaning the injectors. Here’s a detailed guide on how to use the machine in clear steps:

- Prepare the Machine and Tools: Before using the CNC-605A, ensure that the machine is placed on a flat and secure surface. Connect it to a power source and check the attached tools, such as the hoses and pipes for the cleaning fluid. Check the cleaning fluid level in the designated tank. It’s important to use a specialized cleaning fluid for fuel injectors to achieve the best results.

- Turn Off the Engine and Disconnect the Injectors: Start by turning off the engine and wait for it to cool completely before starting the disassembly of the injectors. If necessary, lift the car to easily access the injectors, or use an appropriate tool to remove the injectors from the engine. Make sure to stop the fuel flow to the system before handling the injectors to avoid any accidents.

- Prepare the Injectors for Cleaning: Connect the injectors to the CNC-605A injector cleaning machine using the dedicated connectors provided by the machine. The machine may have multiple connectors to allow you to work with different types of injectors. Ensure that the injectors are securely connected to ensure proper cleaning fluid flow.

- Prepare the Cleaning Fluid: Use the cleaning fluid recommended by the injector manufacturer or the cleaning machine’s manufacturer. It’s preferable to use cleaning fluids compatible with the type of fuel used in the vehicle. If the CNC-605A requires mixing the cleaning fluid with another substance, make sure to follow the instructions carefully.

- Select the Appropriate Cleaning Mode: The CNC-605A offers several cleaning modes depending on the injector’s needs. Choose the mode that best suits the type and condition of the injectors. Some of the modes include:

- High-pressure cleaning: Used to remove deposits and accumulated materials that may affect fuel flow.

- Gradual cleaning: Used for cleaning injectors gently in cases of light deposits. Be sure to set the required cleaning time based on the type and condition of the injectors.

- Start the Cleaning Process: After ensuring the settings and connections are correct, turn on the CNC-605A. The machine will begin pumping the cleaning fluid through the injectors using high pressure to clean them effectively. Monitor the digital display on the machine to track the cleaning process. Some machines may have indicators for cleaning time and injector status, which helps you follow the progress.

- Monitor the Cleaning Results: During the cleaning process, ensure that the cleaning fluid is being pumped regularly through the injectors. Some machines may have monitoring systems to ensure there are no leaks or other issues during the process. The CNC-605A may have indicators or notifications to alert you when the cleaning process is complete.

- Turn Off the Machine and Remove the Injectors: After completing the cleaning process, turn off the machine. Make sure to drain any fluid from the machine if required. Carefully remove the injectors from the CNC-605A and ensure they are completely dry before reinstalling them in the engine. Compressed air can be used to speed up the drying process.

- Reinstall the Injectors in the Engine: Reinstall the injectors in their respective places in the engine carefully. Ensure they are securely fastened using the appropriate tools. Check the pipe and cable connections to ensure there are no leaks.

- Test the Engine After Cleaning: After reinstalling the injectors, start the engine to check the injectors’ response and the overall engine performance. You should notice an improvement in fuel consumption and increased engine response. Monitor the engine while driving to see if there are any issues that may have resulted from the cleaning process, such as performance fluctuations or increased fuel consumption.

Warranty and Technical Support from Launch Saudi Arabia

Launch Saudi Arabia provides a warranty and technical support for the CNC-605A car injector cleaning machine, a device specialized in cleaning fuel injectors using steam or specific cleaning fluids. This machine helps improve car engine performance by effectively cleaning the fuel injectors, which increases efficiency and reduces fuel consumption.

Warranty:

- Warranty Duration:

The device comes with a specified warranty from the company, usually ranging from 12 to 24 months, depending on the terms outlined in the sales contract or invoice. During the warranty period, any faults or defects in the machine due to manufacturing or material issues will be repaired. - Coverage:

The warranty covers malfunctions caused by manufacturing defects or raw material issues. This may include parts such as pumps, wires, or electrical components.

Damage caused by improper use or neglect may be excluded from the warranty. - Exclusions:

- Failures caused by component damage due to misuse, such as using inappropriate fluids or exposing the device to shocks.

- Failures occurring after the warranty period or due to unauthorized modifications to the device.

Technical Support:

- Customer Service:

Launch Saudi Arabia offers dedicated customer service to help resolve any issues customers may face while using the CNC-605A car injector cleaning machine. - Phone or Email Support:

Users can contact the technical support team via phone or email for inquiries or technical guidance on using the device or troubleshooting specific issues. - Training and Instructions:

Launch typically provides training sessions or workshops for automotive technicians on how to use and maintain the CNC-605A effectively. - Spare Parts:

If replacement parts are needed, Launch provides original spare parts to support the maintenance of the device and ensure it continues to function well. - Routine Maintenance:

Routine maintenance can also be performed on the machine through authorized agents to ensure the device operates at optimal efficiency for a longer period. - Remote Support:

In some cases, the technical support team may provide remote assistance using technologies like video calls or troubleshooting software to diagnose issues.

How to Benefit from the Warranty and Technical Support:

- Contact an Authorized Service Center:

If there’s an issue with the machine, contact the authorized service center of Launch Saudi Arabia. - Provide Purchase Invoice:

You may be asked to provide the purchase invoice or proof of purchase to activate the warranty. - Repair or Replacement of Devices:

If the issue is covered by the warranty, the device will either be repaired or replaced if the fault is non-repairable.

If you purchased the device from an authorized dealer or local distributor, you can also contact them for assistance or additional guidance.

Functions of the CNC-605A Car Injector Cleaning Machine:

- Ultrasonic Cleaning: Cleans the injectors to completely remove carbon deposits.

- Spray/Equilibrium Testing: Tests the uniformity of the fuel injected by each injector and monitors the spray pattern for each injector using backlighting.

- Leak Testing: Tests the sealing condition and prevents leakage of the injectors under system pressure.

- Injection Quantity Testing: Checks the amount of fuel injected by the injector within 15 seconds of continuous injection.

- Automatic Testing: Tests the injectors using pre-programmed settings.

- On-Vehicle Cleaning: Cleans injectors installed in the vehicle to remove carbon deposits.

- Setup: Allows system language adjustment.

- Inquiry: Displays device usage information.

- Information: Checks the version of the hardware and software.

Features of the CNC-650 Injector Cleaning Machine:

- Uses powerful ultrasonic cleaning technology to provide complete cleaning of injectors/pumps.

- Provides consistent test pressure and a wide range of adjustment controlled by a precision computer.

- With precise computer control and an LCD display, the machine enables automatic cleaning, injector testing, and real-time dynamic value monitoring.

- Automatically drains fuel through pre-programmed settings for certain device tests.

- Simplified design allows quick restoration of system pressure to default values.

- LCD display shows detailed operating information.

- Touch buttons for easy operation.

Why Choose the CNC-605A Injector Cleaning Machine from Launch Saudi Arabia?

The CNC-605A from Launch Saudi Arabia is an advanced injector cleaning machine that uses modern and advanced technologies to clean car injectors. This machine is one of the ideal solutions for improving car engine performance, thanks to its high efficiency in removing deposits and impurities accumulated inside the injectors. If you’re looking for a high-performance injector cleaning machine, the CNC-605A from Launch is the best choice. Here are the reasons that make this machine stand out:

-

Advanced Fuel Injector Cleaning Technology:

- Steam and Liquid Cleaning: The CNC-605A injector cleaning machine uses a combination of steam or specialized liquids to clean fuel injectors accurately and effectively. This technology helps in removing deposits that may affect injector performance, enhancing engine efficiency and reducing fuel consumption.

- Restoring Engine Efficiency: By using the CNC-605A injector cleaning machine regularly, you can improve engine performance and ensure more efficient fuel consumption.

-

User-Friendly Design:

- Simple User Interface: This injector cleaning machine is equipped with an easy-to-use control panel, making the operation of the machine and injector cleaning a simple task, even for new users.

- Multiple Functions: The machine allows cleaning fuel injectors for different types of cars, and you can adjust it to meet your specific needs based on the engine type.

-

Precision and Efficiency:

- High Performance: The CNC-605A injector cleaning machine provides powerful performance, helping to clean injectors effectively and in a short time. Thanks to this efficiency, maintenance workshops can offer faster and more accurate service to customers.

- Diagnostic Technology: The machine also includes advanced diagnostic technology to check the condition of the injectors and determine if they need cleaning or replacement.

-

Reliability and Technical Support from Launch Saudi Arabia:

- Long Warranty and Continuous Technical Support: The CNC-605A injector cleaning machine comes with comprehensive warranty coverage from Launch Saudi Arabia, ensuring peace of mind in case of any technical issues.

- After-Sales Service: Launch Saudi Arabia offers excellent technical support, with authorized service centers ensuring the machine operates at its best.

-

Reduce Long-Term Maintenance Costs:

- Extended Engine Life: Regular injector cleaning with the CNC-605A helps maintain engine performance, reducing the need for costly repairs and extending engine life.

- Fuel Savings: Injector cleaning improves fuel combustion efficiency, leading to long-term savings by reducing fuel consumption.

-

Ease of Maintenance and Spare Parts:

- Easy Maintenance: The CNC-605A is designed for easy maintenance. If any parts need to be replaced, original spare parts are available through authorized service centers.

- Availability of Original Spare Parts: When purchasing the CNC-605A injector cleaning machine, you can rely on the availability of original spare parts for machine maintenance and continued efficiency.

-

Accurate and Fast Results:

- Comprehensive Cleaning: The CNC-605A provides thorough cleaning of injectors, addressing injector nozzles and other components that may accumulate deposits.

- Works with Various Car Types: The machine works with various car and vehicle types, including gasoline and diesel engine cars.

-

Excellent Value for Money:

- Long-Term Investment: Compared to other machines in the market, the CNC-605A provides excellent value for money due to its efficiency, outstanding technical support, and long service life.

-

Customizability:

- Customizable Settings: The machine can be customized to work according to the needs of different workshops, allowing users to adjust machine parameters to suit different types of engines and injectors.

-

Durability and High Quality:

- Durable Manufacturing Materials: The CNC-605A is manufactured using high-quality materials, making it a strong and versatile machine for workshops that handle large volumes of vehicles.

Frequently Asked Questions about the CNC-605A Car Injector Cleaning Machine

The CNC-605A car injector cleaning machine is an essential tool for vehicle maintenance and ensuring engine efficiency. Below are some frequently asked questions and their answers regarding this machine:

- What is the CNC-605A machine?

- It is a specialized machine for cleaning and testing fuel injectors used in cars. The machine removes deposits and carbon from inside the injectors to ensure smooth fuel flow.

- What are the main functions of the car injector cleaning machine?

- Ultrasonic cleaning of injectors: Removes deposits inside the injectors.

- Injector performance testing: Allows testing of fuel flow and operating pressure.

- Cleaning injectors while in operation: Can be used to clean injectors while they are installed in the car.

- Fault diagnosis: Helps identify injectors that need repair or replacement.

- Is the machine suitable for all types of cars?

- Yes, the machine supports a wide range of cars, including gasoline cars with multi-injection systems. It is recommended to check the user manual to ensure compatibility with your vehicle type.

- What is the cleaning tank capacity?

- The cleaning tank capacity varies by model, but it is usually sufficient for cleaning several injectors at once.

- How do I use the injector cleaning machine?

- Disconnect the injectors from the car.

- Place the injectors in the ultrasonic cleaning tank.

- Start the cleaning cycle.

- After cleaning, use the testing function to check the performance.

- What are the advantages of the machine compared to traditional methods?

- More efficient and precise cleaning using ultrasonic waves.

- Saves time and effort compared to manual cleaning.

- Ensures accurate testing of injector performance.

- Reduces fuel consumption and improves engine performance.

- Does the machine require regular maintenance?

- Yes, to maintain the machine’s efficiency:

- Clean the cleaning tank regularly.

- Ensure filters and pipes are free from dirt.

- Follow the manufacturer’s maintenance instructions.

- Yes, to maintain the machine’s efficiency:

- What safety precautions should be taken when using the machine?

- Use only the recommended cleaning fluids.

- Wear gloves and safety glasses during operation.

- Do not operate the machine without cleaning fluid in the tank.

If you need additional details about the usage or maintenance of the machine, you can refer to the user manual or contact the supplier for further inquiries.

ورشة السلام –

الجهاز رائع ومميز شكرا

المهندس –

مجهود رائع شكرا للمساعدة

ورشة العرب –

تعاملكم راقي شكرا مهندس احمد

ورشة جدة –

الجهاز قيمة للمكان

ورشة العراقي –

والله ماقصرتوا وتستاهلوا كل خير مشكورين

اسلام ميكانيكي –

الجهاز مميزاته والنظام ممتاز جدا

ورشة مكة –

من احسن من تعاملت معهم

ورشة النور –

ممتازين جدا ورائعين

ورشة نويبع –

شكرا لتعاملكم والدورة المميزة

الورشة الحديثة بمكة –

احسن ناس تعاملت معاهم شكرا لكم

هودي للسيارات –

مشكورين

ورشة الشعلة –

شكرا لتعاملكم ومساعدتكم لي

ورشة الدمام العالمية –

مشكوووووووورين على الدورة والمساعدة

ورشة نور –

جزاكم الله كل خير ماقصرتوا تستاهلوا نتعامل معاكم 1000 مرة

ورشة العرب –

شكررررررررررررررررررا

محمد علي –

مشكورين ماقصرتوا

رجب الدمام –

اشتريت من شركات كثير بس انتوا احسن ناس في الدعم والمعاملة الحسنة شكرا مهندس احمد

ورشة الفضاء –

جزاكم الله خيرا ووفقكم ماقصرتوا معاي

محمد العتيبي – الرياض –

خدمة ممتازة، الجهاز استجاب بسرعة والتحديث تم في نفس اليوم، أنصح الجميع.

سلمى الحربي – جدة –

الفريق تعامل بلُطف وشرح كل الخطوات بوضوح. التحديث أحدث فرقاً في أداء سيارتي.

عبدالله الشمري – الدمام –

جربت عدة ورش قبل، لكن خدمات لانش الخليج كانت الأسرع والأفضل من حيث الجودة.

نورة القحطاني – مكة المكرمة –

التشخيص كان دقيقاً وأعدّوني تقريراً مفصّلاً. شعرت أنني فعلاً حصلت على قيمة مقابل مالي.

فيصل الزهراني – أبها –

التعامل احترافي جداً، الأسعار واضحة بدون مفاجآت، والجودة ممتازة.

ماجد السبيعي – بريدة –

الخدمة شاملة — ليس فقط جهاز الفحص، بل شرح لك كل ما يلزم بعد التحديث.

أحمد العنزي – الرياض –

أشكر شركة لانش الخليج على الدورة المجانية المفيدة. الشرح كان مبسط وواضح جدًا، وفريق الدعم متعاون لأبعد حد. تجربة تستحق التقدير!

مشعل القحطاني – مكة المكرمة –

شكراً لانش الخليج على اهتمامكم بالعملاء. الدورة كانت ممتازة والمحتوى متقن، والتعامل راقٍ من أول اتصال حتى التسليم.

فهد الغامدي – المدينة المنورة –

شركة مميزة بكل المقاييس. الأجهزة أصلية والجودة عالية جدًا. أشكرهم على الدورة المجانية التي ساعدتني أفهم الاستخدام خطوة بخطوة

Anonymous –

الورشة الألمانية

ورشة الدمام –

خدمة ممتازة ودعم يستااهل

الورشة الألمانية –

مشكووووووورين خدمة ممتازة